Good User Reputation for Medical Device Injection Molding - China best FCE Consumer manufacturer – FCE Detail:

New Product Development for Consumer Products

EV

EVT

DV

DVT

PV

PVT

Production

PrototypingFast turnaround times for early designs with extensive 3D printing and processing.Finalize an accurate model of the product design.

Rapid prototyping to keep pace with frequent design optimizations.

Basic functional check before investing in the instrument.

Engineering Validation Stage

Rapidly iterate on high-resolution, functional prototypes through rapid injection molding.

A high-resolution functional prototype for comparing configurations.

High-quality design options for the design of experiments.

Optimise material properties for your designs.

Design Validation Stage

Validate the strength, function and aesthetics of parts by production injection molding, which are also high-quality parts for reliability and life testing.

High quality components for reliability and life cycle testing.

Verify appearance and durability of surface finish.

Mass production process capability design.

Production Validation Stage

Prepare your designs with transparent documentation and advanced quality control services to improve production processes.

Run fixtures to verify production part functionality and yield.

Tight tolerances for precision parts during production.

Fully functional PPAP parts for customer approval.

Production Stage

Transition seamlessly to production and incorporate your precise quality requirements into the FCE Manufacturing System.

All process parameters have been identified and documented.

All yields on production parts are within requirements.

All capacities meet requirements.

Faster Develop Time

FCE ensure your consumer products from concept to achievable products. FCE engineers can reduce develop time by as much as 50%.

Professional Support

Our engineers all from Leading Consumer Product Companies with senior experience. We know how to handle your requirements throughout our process.

Seamless Transition to Production

FCE offers a wide range of manufacturing capabilities. Enabling customers to rapidly scale from 3D printing to Injection molding with a single partner.

Ready to Build?

Questions?

Resources for Consumer Product Engineers

The seven components of injection mold, do you know?

Mechanisms, ejector and core-pulling mechanisms, cooling and heating systems, and exhaust systems are categorized by function. The analysis of the seven sections is as follows:

Mold customization

FCE is a company specializing in the manufacture of high-precision injection molds, and is engaged in the manufacture of medical, two-color molds, and ultra-thin box in-mold labeling. And the development and manufacture of household appliances, auto parts, daily necessities molds.

Mold development

In the manufacturing process of various modern products, the existence of processing tools such as molds can bring more convenience to the entire production process and improve the quality of the produced products.

Custom Parts for Consumer Products

At FCE, we provide a one-stop end-to-end service with the resources to handle large projects combined with flexibility and attention to detail.

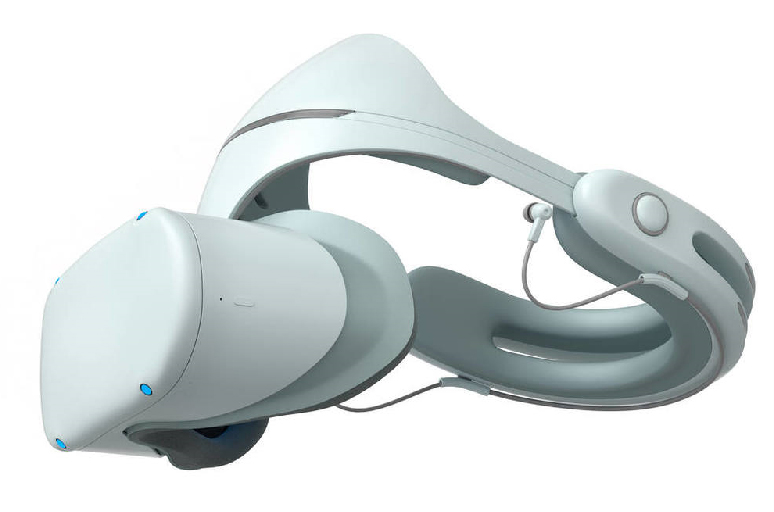

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Good User Reputation for Medical Device Injection Molding - China best FCE Consumer manufacturer – FCE , The product will supply to all over the world, such as: Sao Paulo, Auckland, South Korea, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.