CNC Machining Service

CNC Machining Available Process

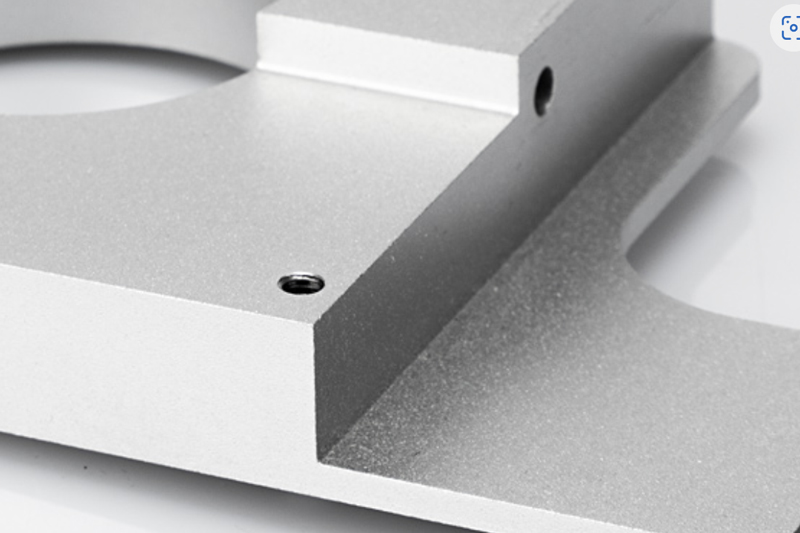

CNC Milling Service

With over 50sets of 3, 4, and 5-axis CNC machines to provide the highest tolerance up to ±0.0008″ (0.02 mm) Precision CNC milling parts. Online machine shop for prototype machining and production.

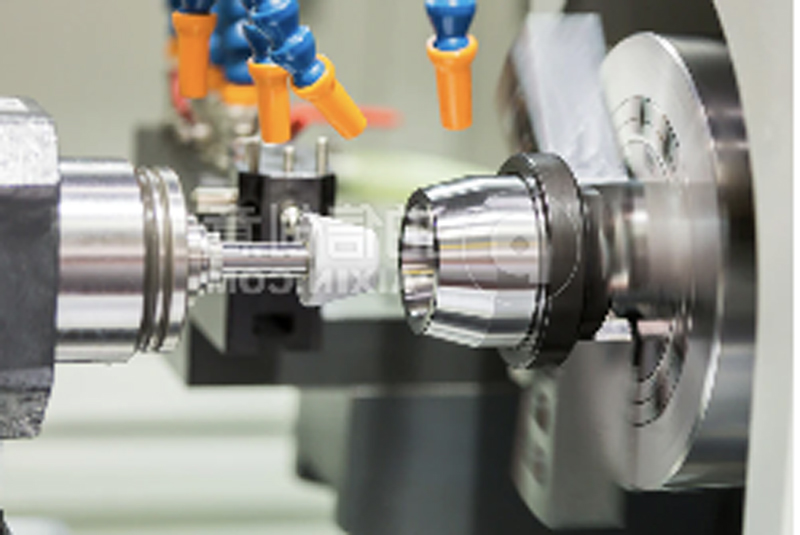

CNC Turning Service

80+ CNC Lathes and CNC turning centers, can provide cost-effective precision machining services with quick response. 15+ years professional engineers to support with complex products.

Electrical Discharge Machining(EDM)

A non-contact machining method for delicate structures. two types of Electrical Discharge Machining (EDM) processes we offer, Wire EDM and Sinker EDM. The processes are useful for cutting deep pockets and complex features such as gears and holes with a keyway.

CNC Machining Applications

Rapid Tooling

CNC machining is a perfect solution to create fixtures or molds. CNC machining can cut a high variety of fully dense, durable materials like aluminum 5052 and stainless steel.

Rapid Prototyping

Prototypes to be ready in 1 day. We have 20+ skilled machinists to support rapid and high-quality prototypes. A variety of affordable metal alloys and plastics can be applied for prototypes.

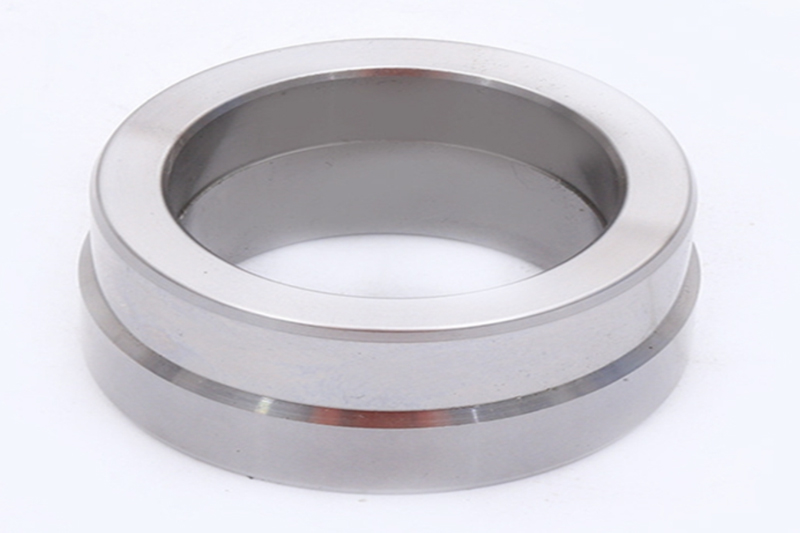

End-Use Production

Tight tolerances as low as +/- 0.001”, certifiable material options and various surface treatment processes make CNC machining an excellent technology for end-use parts. Thousand pieces to be ready in days.

CNC Machining Materials Selection----Metal

FCE will help you find best material according to the product requirement and application. Choose between fast and cost-effective options to find the best material.

·CNC Machining Aluminum Alloys

Aluminum 6061

Aluminum 5052

Aluminum 2024

Aluminum 6063

Aluminum 7050

Aluminum 7075

Aluminum MIC-6

·CNC Machining Copper Alloys

Copper 101

Copper C110

·CNC Machining Bronze Alloys

Copper C932

·CNC Machining Brass Alloys

Copper 260

Copper 360

·CNC Machining Stainless Steel Alloys

Nitronic 60 (218 SS)

Stainless Steel 15-5

Stainless Steel 17-4

Stainless Steel 18-8

Stainless Steel 303

Stainless Steel 316/316L

Stainless Steel 416

Stainless Steel 410

Stainless Steel 420

Stainless Steel 440C

· CNC Machining Steel Alloys

Steel 1018

Steel 1215

Steel 4130

Steel 4140

Steel 4140PH

Steel 4340

Steel A36

·CNC Machining Titanium Alloys

Titanium (Grade 2)

Titanium (Grade 5)

·CNC Machining Zinc Alloys

Zinc Alloy

CNC Machining Materials Selection---- Plastic

FCE will help you find best material according to the product requirement and application. Choose between fast and cost-effective options to find the best material.

·ABS

ABS is easily machined via standard machining techniques , such as turning, milling, drilling and sawing.

·Acrylic

A clear glass-like plastic, is commonly used for outdoor use. Good wear and tear properties.

·Delrin (Acetal)

Delrin is with good moisture resistance, high wear-resistance, and low friction.

·Garolite G10

G10 is Strong, machinable and electrically insulating. It’s made of a flame-retardant epoxy resin with fiberglass fabric reinforcement.

·HDPE

High-density polyethylene is a moisture and chemical-resistant plastic with good impact strength. Commonly used for outdoor applications , watertight containers and seals.

·Nylon 6/6

Nylon 6/6 increased mechanical strength, rigidity, good stability under offers heat and/or chemical resistance.

·PC (Polycarbonate)

PC has superior mechanical and structural properties. Used widely in automotive, aerospace, and other applications that require durability and stability.

·PEEK

PEEK is often used as a lightweight alternative material for metal parts. Commonly used in high-temperature, high-stress applications. PEEK resists chemicals, wear, and moisture, offering excellent tensile strength,

·Polypropylene

Polypropylene is chemical or corrosion resistance. It has excellent electrical properties and little or no moisture absorption. It carries light loads for a long period in widely varying temperatures.

·PTFE (Teflon)

PTFE surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator.

·UHMW PE

Ultra-high molecular weight polyethylene. UHMW PE does not absorb moisture and it offers a unique combination of wear and corrosion resistance, high chemical resistance, low surface friction, high impact strength.

·PVC

PVC is commonly applied in environments exposed to liquids or requires electrical insulation. And is also highly chemical-resistant synthetic plastic

CNC Machining Surface Finishes

Standard (As-Milled)

It’s the quickest turnaround machining process. It has a surface roughness of 3.2 μm (126 μin). All sharp edges are removed, and parts are deburred. Tool marks are visible.

Bead Blast

Part surface is left with a smooth, matte appearance

Tumbled

It’s the quickest turnaround machining process. It has a surface roughness of 3.2 μm (126 μin). All sharp edges are removed, and parts are deburred. Tool marks are visible.

Anodized

Parts can be anodized in many different colors—Clear, black, grey, red, blue, gold.

Passivation

Parts can be anodized in many different colors—black, clear, red, and gold.

Powder Coat

Parts can be anodized in many different colors—black, clear, red, and gold.

CNC Machining Design Guidelines

| Feature | Description |

| Internal corner fillets | Design internal corner fillets to be 0.020” - 0.050” greater than a standard drill size for the radii. Follow a drill diameter to depth ratio of 1:6 (1:4 recommended) as a guideline for internal corner radii. |

| Floor fillets | Design floor fillets smaller than corner fillets to allow the same tool to clear material from the interior. |

| Undercuts | Always design undercuts to standard sizes and away from corners so they are accessible by the cutting tool. |

| Tapped/threaded hole depth | Provide tool clearance slightly beyond the tapped hole depth to ensure complete threads. |

| Complexity | Keep the number of small cuts to a minimum to reduce CNC machining costs; only design in the necessary features to balance function with aesthetic. |

CNC Machining Tolerances

| Feature | Description |

| Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter. |

| Standard Lead Time | 3 business days |

| General Tolerances | Tolerances on metals will be held to +/- 0.005" (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”. |

| Precision Tolerances | FCE can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts. |

| Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | FCE can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

| Edge Condition | Sharp edges are broken and deburred by default |

| Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

Our Quality Promise