Main Services

FCE gives you access to a wide range of capabilities through an end-to-end platform in a variety of

markets. Fully to address major customer needs.

Industries

Professional Team Focus On Your Project

-

Easy communication since we know your product

Our sales engineers have a deep technical background and extensive industry experience. No matter you are a technical engineer, designer, project manager or procurement engineer etc., you will quickly feel how well they understand your product and quickly provide valuable advices.

-

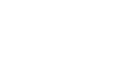

Dedicate team micro- management for your project

Dedicated project team to micro-manage each project. The team is composed of experienced product engineers, electro-mechanical engineers, industrial engineers and production engineers according to the characteristics and needs of the product. Makes the development work efficient and high quality.

Leading Engineering, Top Brand Facilities,

Micro Production Management

-

Design Optimization

We have rich experience at material selection, mechanical analysis, manufacture process. Each project solutions to optimize Product quality, manufacture cost. Complete finite element analysis software to predict and prevent most of manufacturing issues before cost generated

-

Clean room production

Our cleanroom injection molding and assembly areas provide an effective way to manufacture your medical parts and components to fulfil specification requirements. Products from the clean room are delivered to class 100,000 / ISO 13485 certified environment. The packaging process is also performed within this controlled environment to prevent any contamination.

-

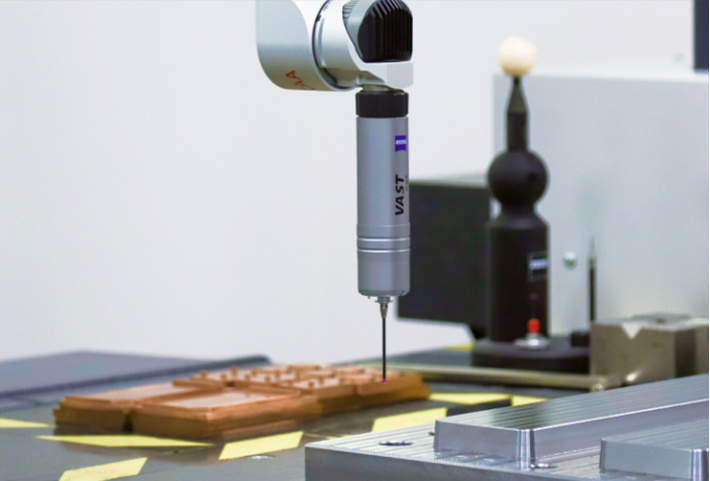

Quality Assurance

Precision CMM, optical measuring instruments equipment are the basic configuration to detect the quality of the finished product. FCE does much more than that, we spend more time identifying potential causes of failure and the corresponding preventive measures, testing the effectiveness of the prevention.

Try FCE now,

All information and uploads are secure and confidential.